Latest News: Participating again in Water, Energy, Technology & Environment Exhibition (WETEX-2024)

A mechanical component that transmits rotation and power from one shaft to another. It is a machine component in which the rotary power is transmitted by the prime mover’s tooth surface pushing the tooth surface of the driven shaft.

Helical Gear

Used with parallel shafts similar to spur gears and are cylindrical gears with winding tooth lines. They have better teeth meshing than spur gears and have superior quietness and can transmit higher loads, making them suitable for high-speed applications.

Advantages: Perfect gear meshing between pinion and wheel whatever the deformation of the shaft of the driven machine. Perfectly adapted to transmissions with very high torque at low speeds, it perfectly meets the high requirements of strategic machines in the steel, cement, sugar and other special applications industries. Suitable for applications generating very high loads, and is suitable for impact applications

Worm Gear

A screw shape cut on a shaft is the worm, the mating gear is the worm wheel, and together on non-intersecting shafts is called a worm gear.

Availability: We offers a range of worm gear reducers and gear motors with or without incorporated primary helical gear trains, providing a power range from 0.75 kW to 160 kW. These reducers and gear motors are available with hollow or standard output shafts from 25mm to 140mm in diameter (larger diameters available on request).

Advantages: Orthogonal shaft orientation, Hollow Shaft assembly, High Reduction Ratio Obtained in Little Space.

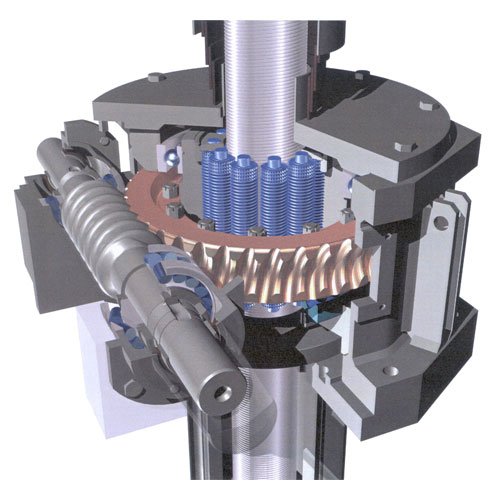

Internal (Planetary) Gear

Internal gears have teeth cut on the inside of cylinders or cones and are paired with external gears. The main use of internal gears are for planetary gear drives and gear type shaft couplings.

Design: Input speed from 600 rpm to 1800 rpm; Output speed from about 3 rpm to 7 rpm; Bearings lifetime L10H> 100 000 h according to ISO 281 standard.

Advantages: Heavy duty design, suitable to withstand load and speed variations induced by sugarcane milling; Sufficient bearings size selection for maximum lifetime; Easy inspection and maintenance by quick access to gears and bearings (less than 30 min); Over torque detection in output stage for enhanced safety.

Girth Gear

Designs and manufactures large open gears & pinions.

Services: Facility diagnostics, on-site surveys, calculation of load capacities, definition and optimization of the design of products and their material, resizing of assembly bolts parts of the gear (in half or quarter), manufacturing, control with machine meshing test if necessary, installation on site and maintenance assistance.

Capacities: Heat treatment: 12m x 6m x 3.5m or Ø 9m; Machining: 16 m; Boring: 16m x 3.5m; Cutting: 16 m – module 60 mm

Rotors

Compressor screws and rotors are used in mainstream industry, for air compressors, fluid transfer, lifting Equipment.

Availability: Screw compressor rotors; Hydraulic Pump Screws, Serial Production of Worms.

Capabilities: Manufacturing of prototypes as well as serial production (50 – 1500 pcs / yr); Thread grinding up to Ø 400mm – threaded length up to 1400mm; Grinding quality ISO 5; Thread measurement: profile, pitch, parallelism, division, pcd; Backlash measuring Bench.