Latest News: Participating again in Water, Energy, Technology & Environment Exhibition (WETEX-2024)

Motors

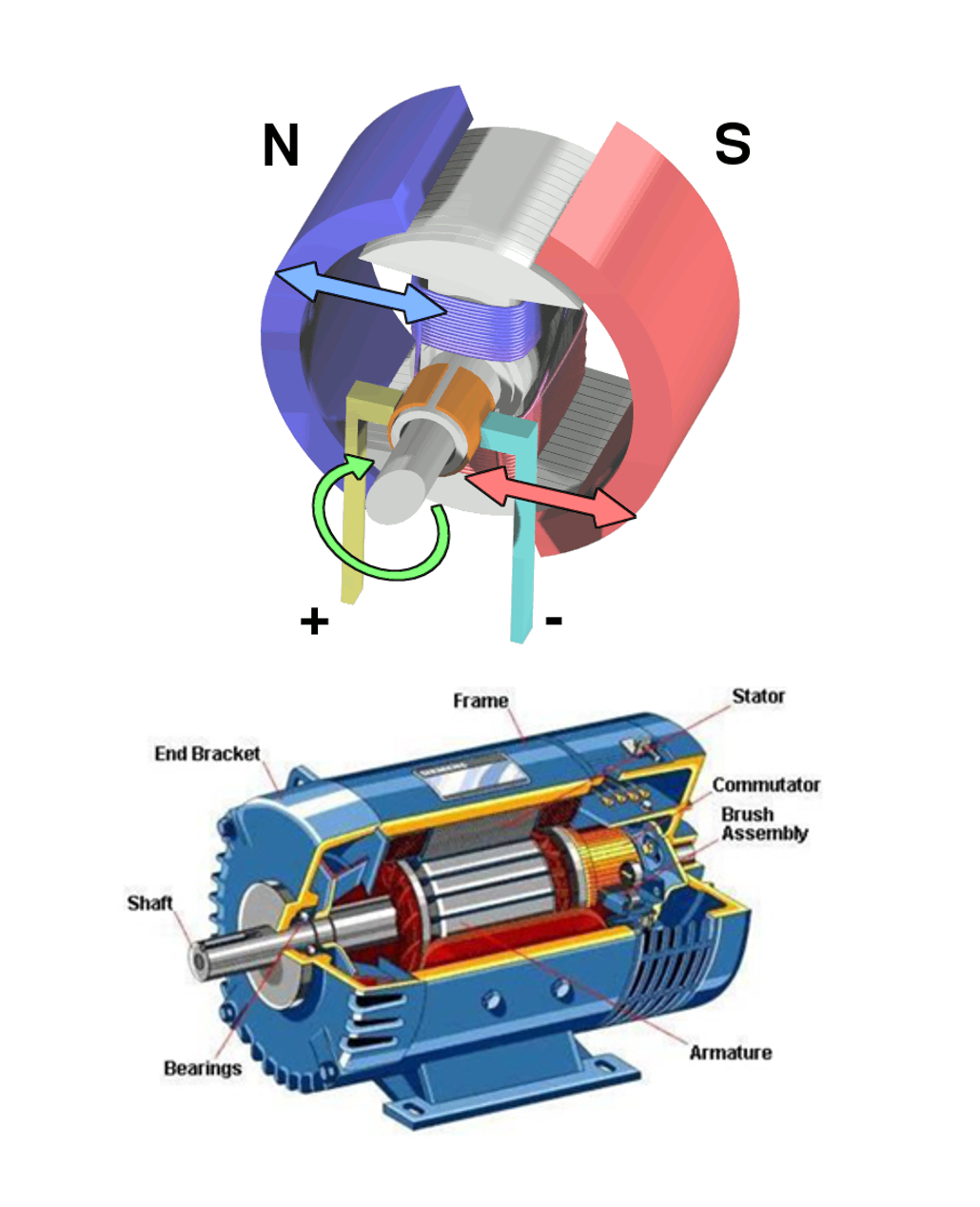

DC MOTOR

DC MOTOR: operated by DC (direct current) is known as a DC motor (unlike an induction motor that operates via an alternating current). A DC motor converts DC electrical energy into mechanical energy.

Applications: Used where high starting torque and accurate speed control over a wide range are important and also suitable for both high and low power drives, for fixed and variable speed electric drives such as Cranes, Air Compressor, Elevators, Conveyors, Fans, Blowers, Centrifugal Pumps.

Advantages: Good Speed Control, High Torque, Seamless Operation, Free from Harmonics.

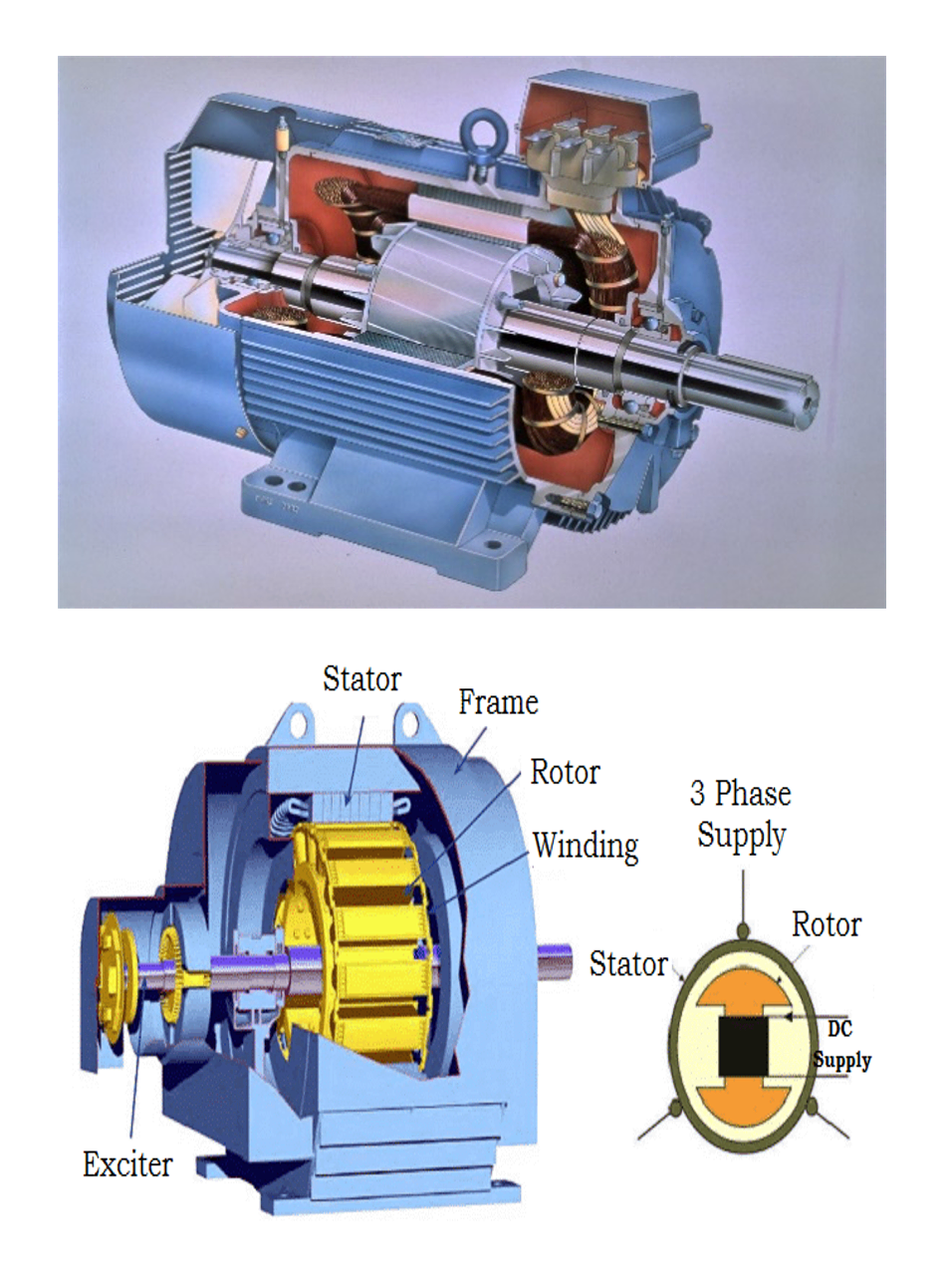

Synchronous Motor

(short for synchronous electric motor) is an AC motor where the rotation of the rotor (or shaft) is synchronized with the frequency of the supply current. That is, the rotation period of the rotor is equal to the rotating field of the machine it is inside of.

Applications – Synchronous motor finds applications where operating speed is less (around 500 rpm) and high power is required. Ex- Reciprocating pump, Air and gas compressor, rolling mills, vacuum pumps, crushers, mills and grinders, exhausters, fans and blowers.

Advantages – Ability to control the power factor. Speed remains constant irrespective of the loads, built with wider air gaps than induction motors which makes them mechanically more stable, operated with higher efficiency (more than 90%) especially in low speed.

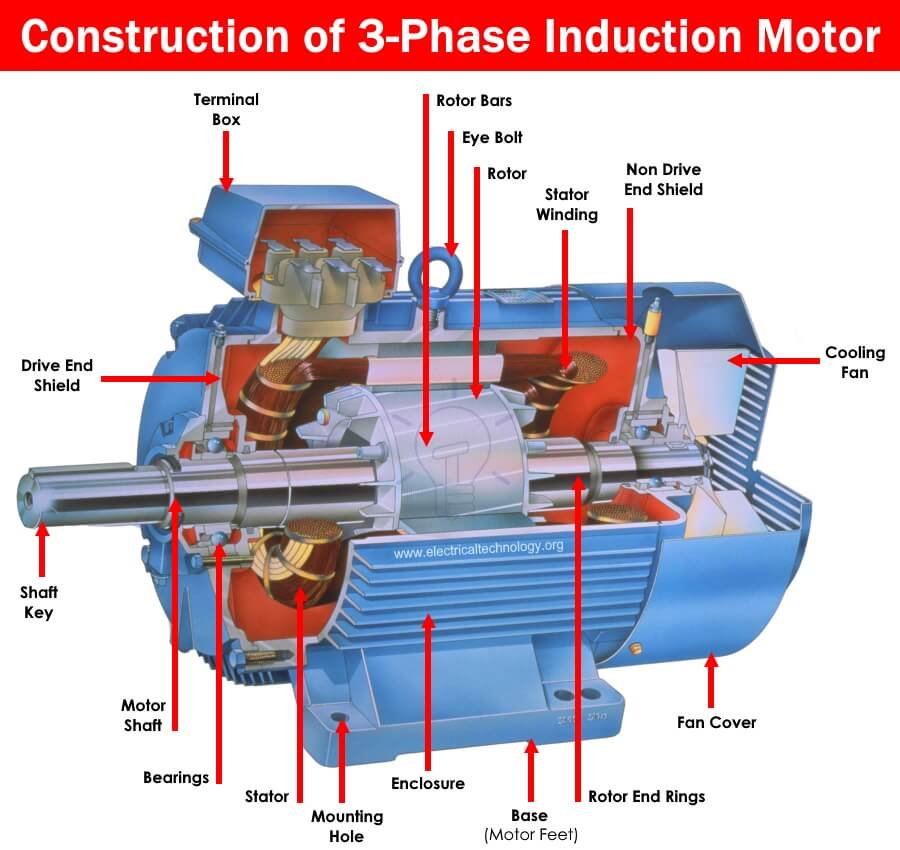

Phase Induction Motor

Runs on three-phase power supply. The benefit of a three-phase alternating current is that it generates a rotating magnetic field in the stator while the arrangement of the phases decides the direction of the rotation. These motor does not need any special starting mechanism to decide its direction and also known as self-starting induction motors. It is consisted of Two Major Parts a Stator and a Rotor.

Applications: Pumps, Compressors, Conveyors, Steel Mills, Cranes, Line Shafts, Hoist.

Advantages: It has simple and rugged construction, less maintenance, high efficiency and good power factor, less expensive and self-starting torque.

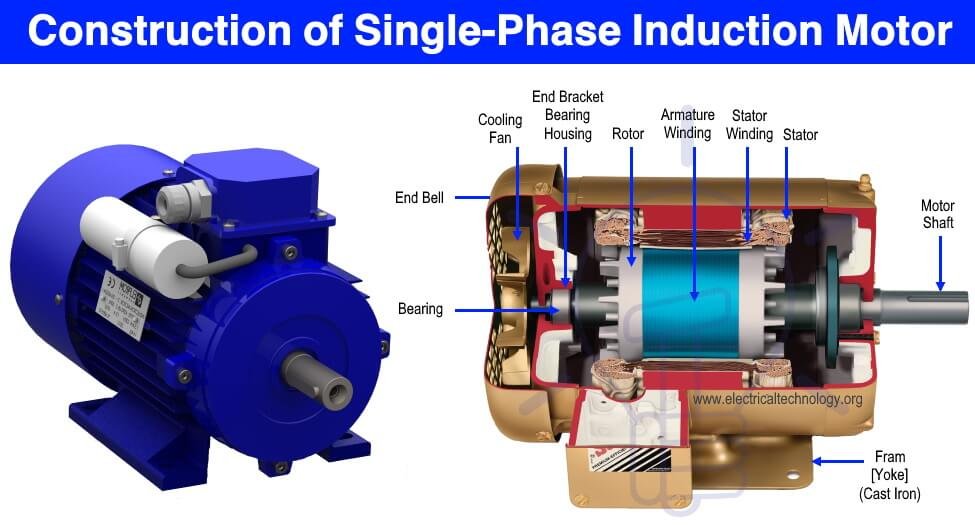

Single Phase Induction Motor

Runs on single-phase AC supply. To be precise, it actually uses two-phase, the second one being derived from the first phase. The reason for using two phases is that a single phase cannot generate a rotating magnetic field. It is used for domestic purposes, commercial purposes, and some extent in industrial uses. These motors are simple in construction, cheap in cost, reliable and easy to repair and maintain.

Applications – are used in smaller equipment where we require less horsepower such as Pumps, Compressors, Small Fans, Mixers, Drilling Machines.

Advantages – smaller in size and lighter in weight, cheaper in cost, highly efficient, less maintenance, longer life and can be designed in a variety of sizes.

Special Motors

Servomotor

SERVOMOTOR: is the one in which the output is the mechanical variable like position, acceleration, velocity. It has a low power rating and can drive the load directly. That’s y these motors are usually coupled to the load, through a gear train for power matching purpose.

Applications: Used in Instruments Servos, Process Controllers, Robotics, Self-Balancing Recorders, Machine Tools and Position Control System.

Advantages: High Output Power, Accuracy and resolution are determined by Encoders, High Efficiency, Having 5 to 10 times more rated torque, having 2 to 3 times more rated power.

Stepper Motor

STEPPER MOTOR: special type of DC motor, that converts input digital Pulses into mechanical shaft rotation. It converts a train of Input pulses (square wave pulses) into a precisely defined increment in the shaft position.

Advantages: Used in X-Y Plotters, Floppy Disk Drive, Machine Tools, Process Control System, Robotics, Printers, and variety of Other Industrial Applications.

Universal Motor

UNIVERSAL MOTOR: Can be operated on both DC & single-phase AC supply. This can be also called a “single-phase series motor”. These motors will be having high starting torque.

Applications: Can be used for domestic applications such as vacuum cleaners, food, mixers, hair drains, electric shavers, etc. Can be used in Blowers, portable Tools and small drives, whenever there is a requirement of low and high horsepower.

Advantages: Less costly as compared to other motors, capacity of producing good torque at low speed, the capacity of running at an adjustable speed.

Brushless DC Motor

Brushless DC Motor: These motors do not have brushes in it. Brushless DC electric motor can also be called as electronically commutated motors, which are powered by DC electric source through an integrated inverter or switching power supply, which produces an AC electric signal to drive the motor.

Applications: Can be used in Servo Actuation, Positioning, and variables speed, used in Air conditioners, Used in Biomedical Instrumentations.

Advantages: Low Maintenance Cost, Having Long Life, Low Friction and Low Inertia, High Efficiency (>75%) and Reliable Operation.