Latest News: Participating again in Water, Energy, Technology & Environment Exhibition (WETEX-2024)

Pumps

Chemical Pumps

PFA Lined Magnetic Drive Pumps

These pumps are ideal to meet the stringent requirements of chemical processing and a multitude of other industries. These highly advanced and extremely energy efficient pumps are built to handle a huge variety of corrosive fluids reliably and safely. Eliminating the need for a mechanical seal and therefore making magnetic drive pumps completely leak proof. Designed for high temperature and high pressure, the high purity PFA lining enables handling of high purity chemicals.

Lined Mechanically Sealed Pumps

These Pumps are specifically designed for harsh, abrasive and/or toxic fluids containing solid elements including dirty fluids and high viscosity fluids. With a choice of open or closed impellers on centrifugal pumps, mechanical seal pumps are the right choice for contaminated, dirty or highly viscous fluids.

Dosing Pumps

These pumps are small positive displacement pumps and are designed for metering a wide range of liquids, most especially chemicals. Basically, they inject fluid into a flow of steam, water, or gas. They provide an extremely precise flow rate for a wide range of applications from food processing to wastewater treatment, power generation, chemical processing, petrochemical, and oil and gas processes.

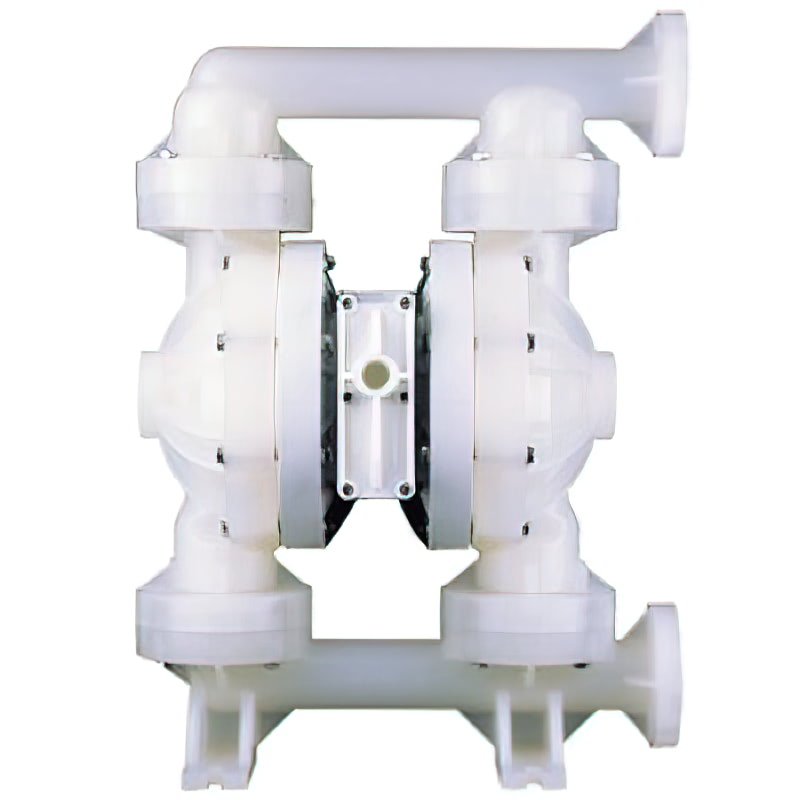

AODD Pump

Air operated double diaphragm pumps (AODD pumps) are designed for general fluid transfer. diaphragm pumps reliably transfer a wide variety of fluids, from clean, light viscosity to medium viscosity. They can pump large particles without damage. Metal or plastic diaphragm pump casings can easily handle corrosive and abrasive fluids.

Water, Sea Water, District Cooling & Irrigation pump

End Suction Pump

The highly efficient end suction pump is one of the simplest types of centrifugal pump that features motor slide rails and a back pull-out design allowing for ready access and ease of maintenance.

Split Case Pump

Horizontal split case pumps are in-line pumps in which the pump housing is divided axially into two parts. Horizontal split case pumps are characterized by their high efficiency and low noise levels, as well as how easy they are to service. The pumps are designed to work in a variety of applications, including HVAC systems, cooling towers, pumping stations, large scale irrigation, river water intake and industrial applications.

Multistage high-pressure Pumps

Multi-stage high-pressure pumps are used for various industrial applications such as water supply, irrigation, for hot and cold-water circulation, firefighting, boiler feed and pressure boosting installations.

Water Waste & Sewage Pumps

Submersible Pumps

Sewage pumps are suitable for sewage, wastewater, and other types of sludge within the municipal, industrial, and private sector. They fulfill high expectations regarding efficiency, life cycle, maintenance friendliness and economic efficiency.

Viscous Fluid Pumps

Peristaltic Pumps

Peristaltic pumps are a form of positive displacement pump suitable for high flow or high-pressure applications and are also known for their ability to handle high solid slurries, viscous products and aggressive fluids.

Progressive Cavity Pumps

One of the most dynamic designs for driving the flow of variety of liquids, Progressive Cavity Pumps can be customized to efficiently handle liquids with different viscosity levels and chemical properties. The Progressive Cavity Pumps comprise of a precision mechanized single external helix metallic rotor and double internal helix elastomer stator. As the rotor turns within stators, the cavity progresses from suction to discharge along with fluid.

Gear Pumps

Gear pump is a type of positive displacement (PD) pump. It moves a fluid by repeatedly enclosing a fixed volume using interlocking cogs or gears, transferring it mechanically using a cyclic pumping action. It delivers a smooth pulse-free flow proportional to the rotational speed of its gears.

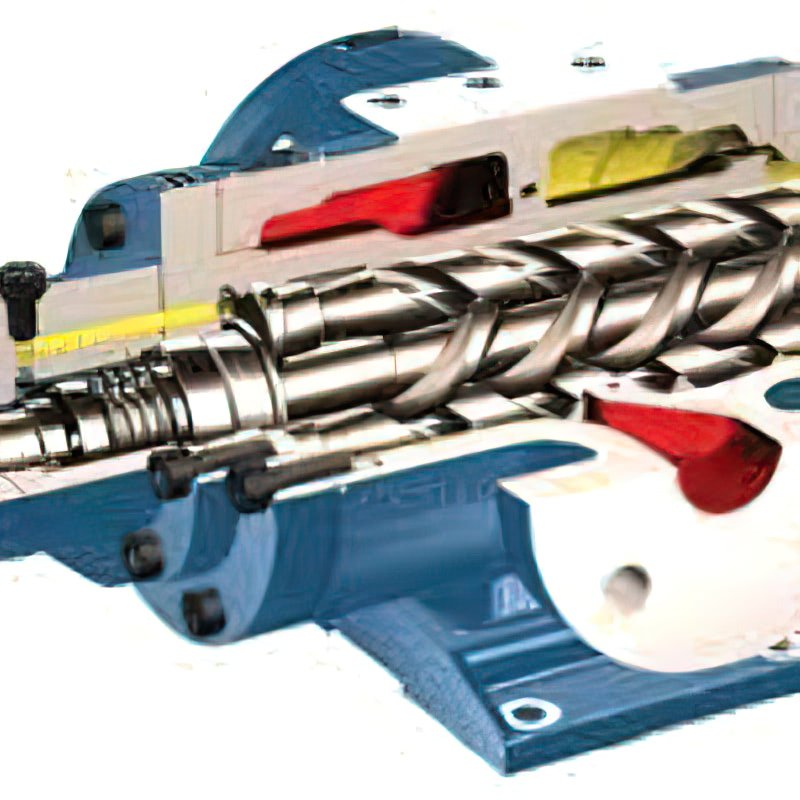

Screw Pump

A screw pump is a type of positive displacement pump that uses two or more screws that intermesh to pressurize fluids and move them in a system. The screws take in fluid then push it out from the other side while increasing its pressure.