Latest News: Participating again in Water, Energy, Technology & Environment Exhibition (WETEX-2024)

Pulse Jet Filter Bags

A filter bag is filtration technology for filtering dust in a baghouse. It separates dust, harmful substances and also products from gas flows.

Filter bags consist of needle felt or fabrics made of synthetic fibers. The needle felt is optimally adjusted for the application case at hand.

Filter bags are used for dust removal processes and for filtering waste gas and exhaust air in industrial plants. They make it possible to comply with the legal limits for (fine) dust emission & thus ensure clean air.

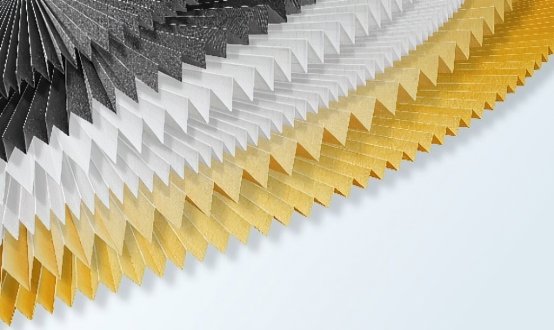

Pleated Filter Bag “Cartridge Filter"

Cartridge filter with increased surface filtration area Cartridge filters is large Diameter (>8” OD) that are used to clean air stream with low to moderate grain loading, while minimizing the footprint of the Dust Collector. The Cartridge Filter has a high cloth area relative to the filter’s height due to the pleated filtration media.

Pleated filters are used in many industries for a variety of applications. Featuring individualized surface and protective treatments.

- Pleated filter medium results in increased filtration area

- High and low temperature filter media, with or without supporting fabric for maximum stability

- Numerous surface and protective treatments possible

- No seam holes, extremely low dust emission

Star Filter Bag” XT-Bags”

A new filtration solution designed to enlarges the filtration surface simply by changing the shape of the filter bag.

Whenever the dust collector is the bottleneck of your production, star bag can be the solution. With an up to 2.5 times larger filtration area. Your production can be increased by keeping the differential pressure constant. Alternatively, you can maintain your production rate while reducing differential pressure and energy consumption. Star bag can easily be installed in an existing filter bag house without any modification in the filter bag house. That is to say, this bag shape can replace any standard round bag by changing cages.

Advantages:

- Same dimensions with an up to 2.5 times larger filtration area

- Same cuff – same installation – new cages

- Higher production capacity with identical filter bag house

- Similar cleaning methods

Delivery Rang:

- Star bags are produced with high & low temperature needle felts media such as PE or m-Aramide

- Various designs according to your requirements

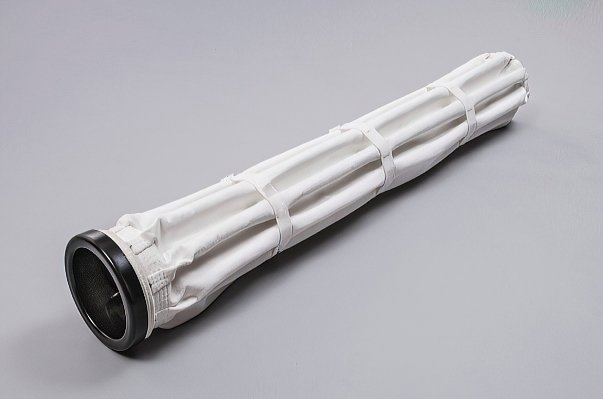

Reverse Filter Bag

Reverse filter bags are suspended from the filter housing at the closed top end and fastened to the head plate at their open bottom end. During filtration, dust-laden gas enters the filter bag from below. As it travels upwards the gas also flows towards the outside, while dust collects on the inside of the filter bag.

To remove the filter cake, the compartment to be cleaned is separated out from the filtration process (taken off-line). A backwash fan then creates a counterflow, causing the filter bag to partially collapse. To prevent total collapse, support rings are sewn along the edge of the filter bag at set intervals. After cleaning, the compartment is brought back into the filtration process (taken on-line).

Advantages:

- Large filter bag dimensions (Diameter up to 300 mm, length up to 12,000 mm)

- Quasi-continuous operation

- For high exhaust gas volumes

- Basis weight is usually between 400 – 450 g/m²